With state-of-the-art machining resources, a skilled workforce and optimally streamlined operations, heat-exchangers have always been our core product. We offer a wide range of Shell & Tube Heat Exchangers, with our forte being high pressure and high/exotic metallurgy exchangers.

Our range of heat exchangers includes Sulphur Condensers, Bayonet Tube exchangers, Catalyst Coolers, Transfer Line Exchangers, Evaporators, High Pressure Feed Water Heaters, Surface Condensers, Waste Heat Exchangers, Multi-Tube Hairpin Exchangers, RG Boilers, etc.

Our collection of high pressure, high temperature and high metallurgy reactors are a great fit for oil and gas refineries, as well as the petrochemical, fertilizer and chemical industries across the globe.

We are very well equipped to supply a wide range of pressure vessels for varied operations in various units of oil & gas, petrochemical, fertilizers and chemical industries. Our offering includes cladded vessels, vessels with high thicknesses and high pressure as well as pressure vessels in special metallurgies.

We are also approved by most gas purification technology licensors for manufacturing critical equipment like Pressure Swing Adsorbers and Temperature Swing Adsorbers (PSA & TSA).

We also offer various columns and towers for the energy sector. Our range of columns and towers includes packed columns as well as tray towers.

Helixchanger®, a shell & tube heat exchanger with helical baffles is a proprietary product of Lummus Technology. These highly efficient exchangers offer major benefits such as lower pressure drop, reduced vibrations, higher heat transfer co-efficient and lower footprint over conventional shell & tube heat exchangers.

ANUP Engineering is one of the few global Licensee who are approved for the complete range of HELIXCHANGER®, HELITOWER®, HELIFIN®, HP-HELIXCHANGER® and HELITURBO®. With experience of more than 200 Helixchangers across various metallurgies, ANUP has fine-tuned and perfected the processes for manufacturing Helix angles ranging from 5° to 40°

Owing to our rich manufacturing experience, we possess a deep understanding of the challenges of manufacturing and the best-suited design to mitigate all such risks and challenges. With this perspective, we also offer pre-fabrication engineering services for static process equipment to our customers, as per the table below.

Design Service |

Equipment Category |

||||

STHE |

ACHE |

Economisers/Steam air heaters/Cooling coils |

Pressure Vessels |

Colums/Reactors |

|

|

Thermal & Hydraulic Design (Preliminary) |

|||||

|

Thermal & Hydraulic Design (Detailed) |

|||||

|

Flow-induced Vibration Analysis (X-vib) |

|||||

|

Mechanical Design (Concise) |

|||||

|

Mechanical Design (Detailed) |

|||||

|

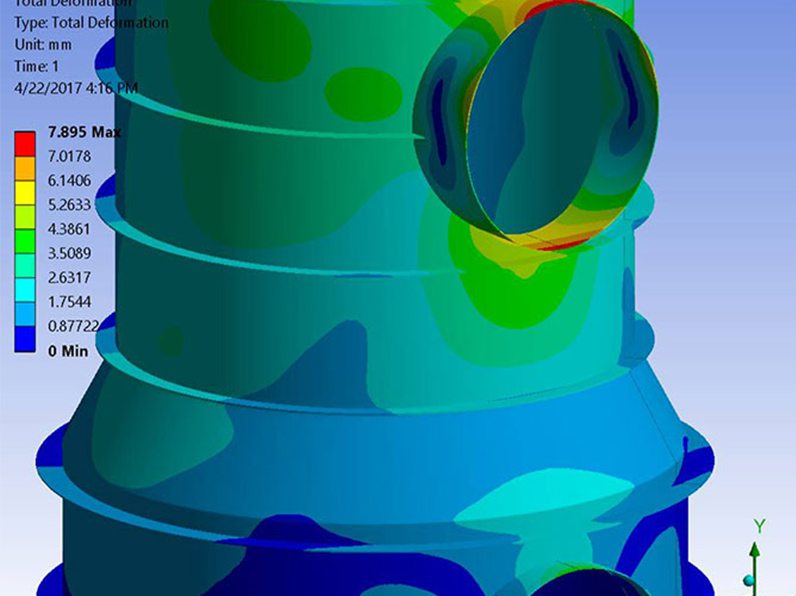

FEA Analysis of process equipment/structural |

|||||

|

Fatigue Analysis (Thermal Transient & Cyclic Loading) |

|||||

|

3-D Modeling |

|||||

|

Drawing- General arrangement |

|||||

|

Drawing- Detailed manufacturing |

|||||

* STHE- Shell & Tube Heat Exchangers; ACHE- Air Cooled Heat Exchangers

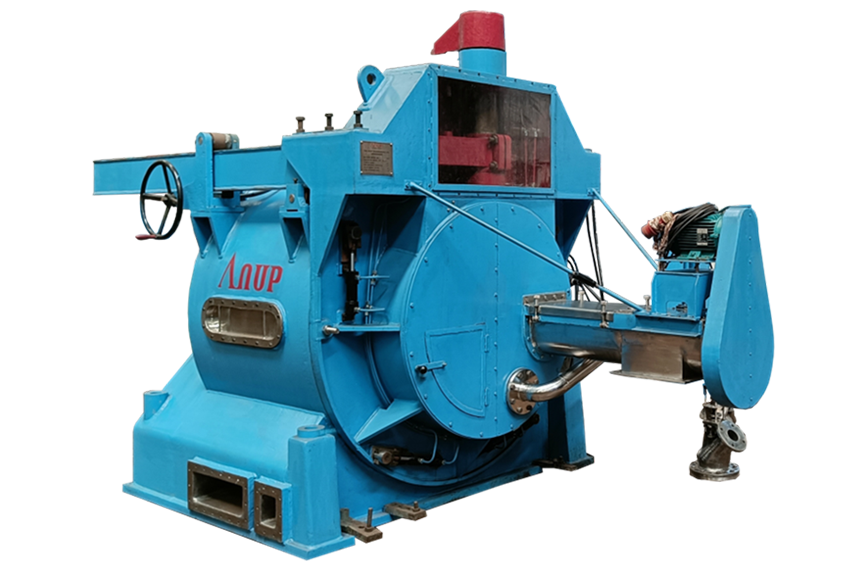

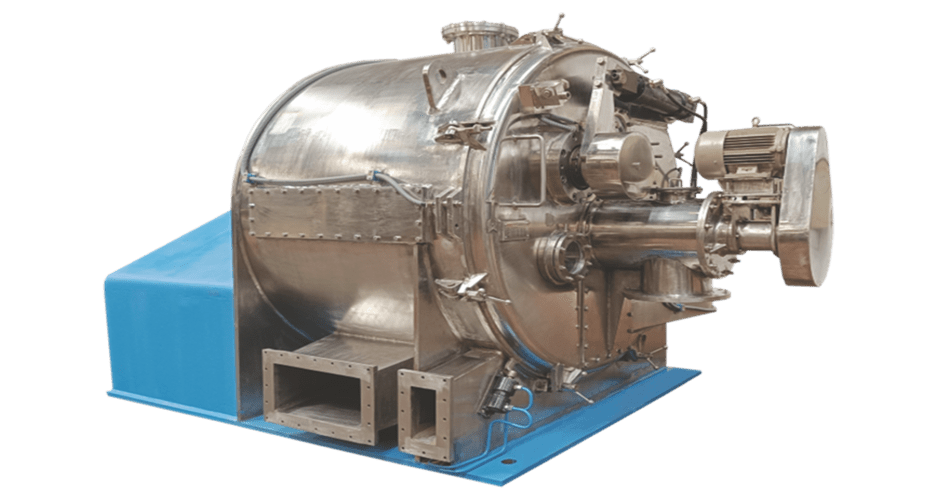

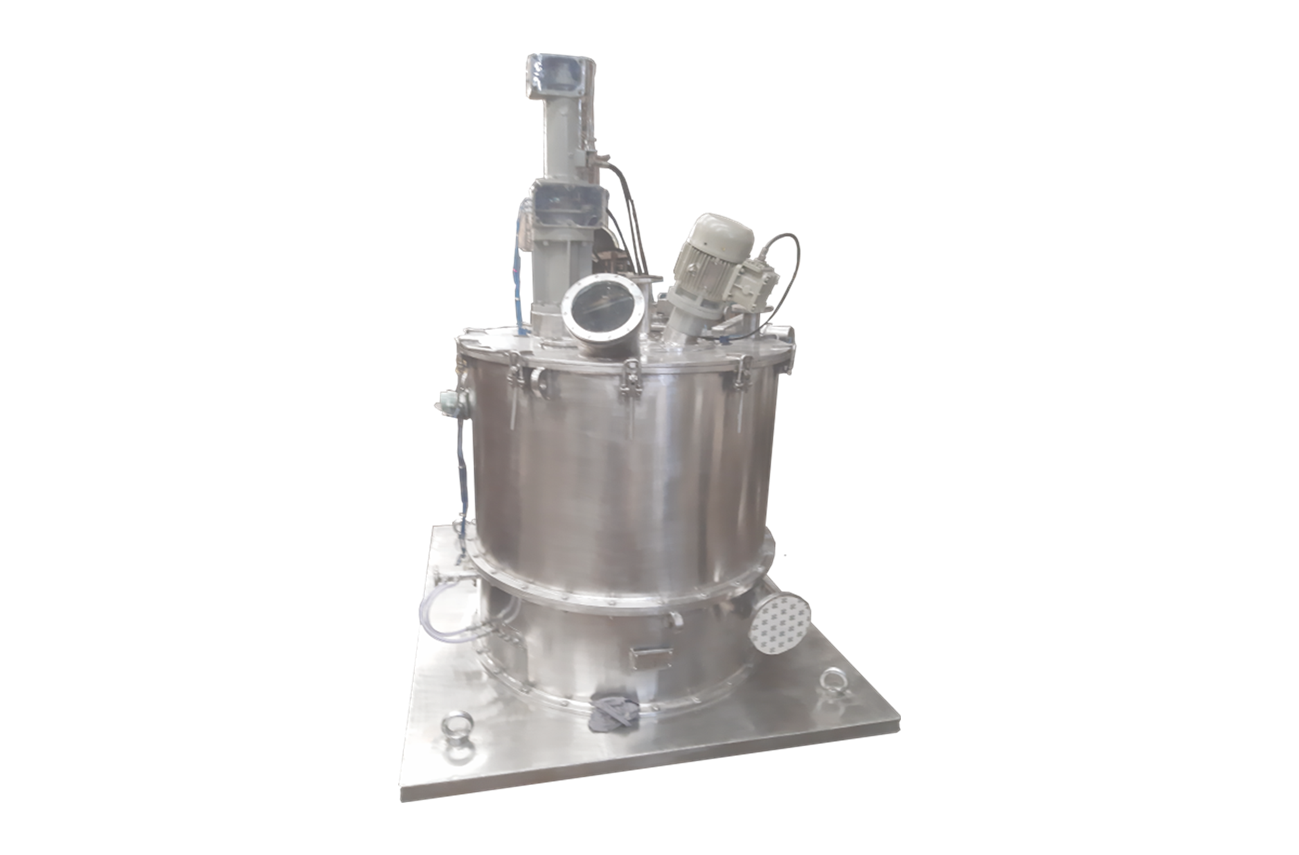

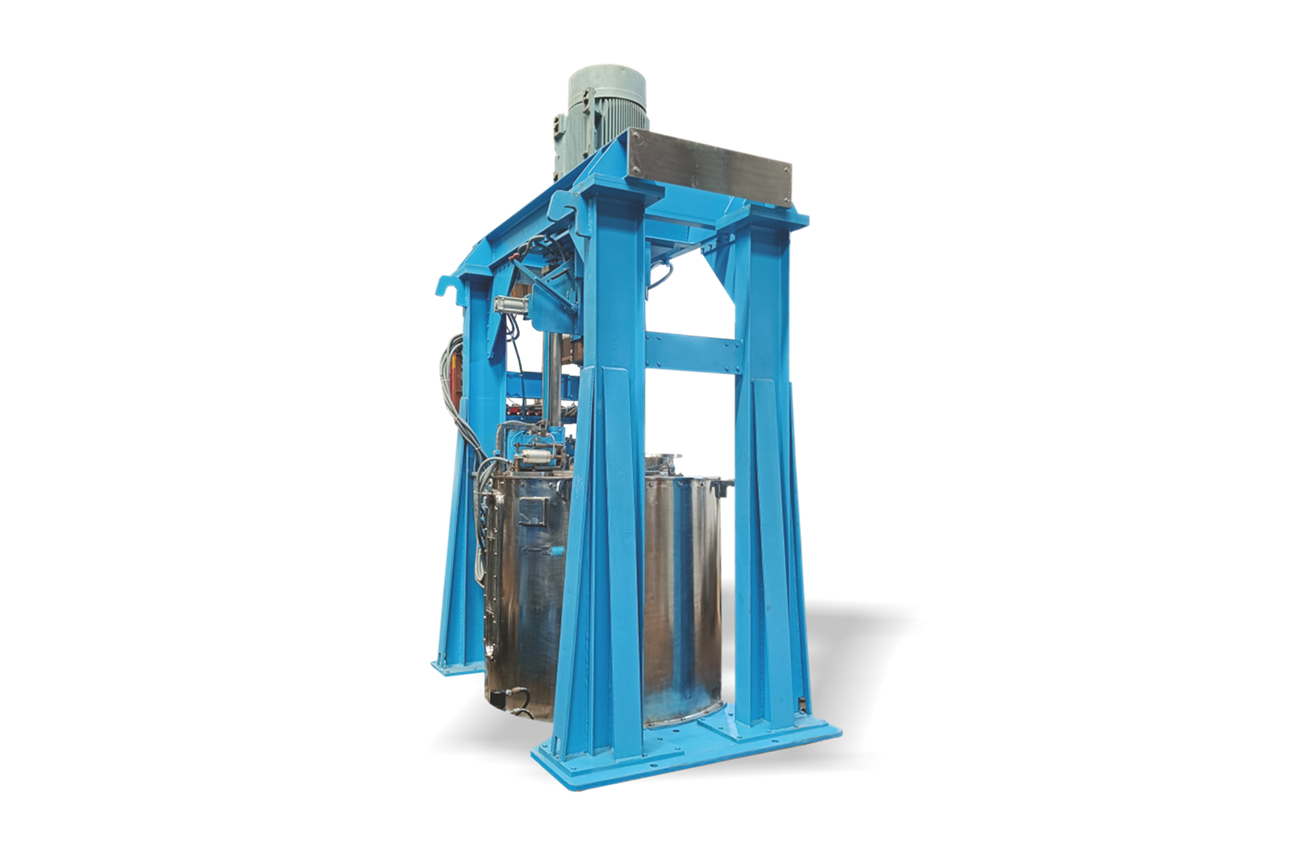

Having been in use for more than 3 decades in the chemicals, fine chemicals, starch and pharmaceutical industries, our range of industrial centrifuges is renowned for its ruggedness and reliability. We offer a complete range of industrial centrifuges – from basket centrifuges (top and bottom discharge) to the horizontal peeler centrifuge.